The #1 Mistake Killing Digital Transformation: Leading with Technology

Too many industrial organizations approach digital transformation as though it is a procurement exercise: pick the “right” technology (AI, robotics, IoT, RPA, etc.), deploy it, and wait for the magic to happen. What often goes missing is the business thinking: what problems are we trying to solve? What value is being foregone today because of broken processes, misaligned capabilities, or lack of data? Is a digital tool even the right remedy?

This upside-down approach — tech first, strategy later — is a well-documented cause of failure. In a bibliometric study of digital transformation, one of the key themes is that many failures stem not from defective technology but from poor coordination, flawed implementation, and lack of alignment with business goals and processes (ScienceDirect). Similarly, analysts repeatedly cite “overemphasis on technology” as a top pitfall: automating chaos only amplifies dysfunction (TechTarget).

Third Stage Consulting, drawing from numerous client recoveries, outlines the four root causes frequently misblamed on tech: people, processes, strategy, and technology — in that order. A broken process, poorly understood customer journey, lack of execution discipline, or culture of resistance will doom any shiny new solution. To put it bluntly:

digital transformation is not about digital first; it is about business transformation enabled by digital.

The Failure Modes You Probably See (or Will See)

Here are the recurrent patterns DX Advisory Solutions has observed (and validated in various studies) in digital transformation projects that falter or never deliver:

| Failure Mode | Description / Signal | Why It Kills Value |

|---|---|---|

| No clear business problem or outcome metric | Teams chase “let’s embed AI in everything,” or “robotics on the shop floor” without articulating which bottlenecks or margins they intend to improve. | You end up with ambiguous ROI, mismatched expectations, and internal pushback. |

| Technology-driven, not outcome-driven | The tech leads the agenda; “process reengineering” is done with the constraints of the tools, not business logic. | You force-fit business logic to tech, inflating cost and creating workarounds. |

| Lack of cross-functional alignment / silos | IT owns the project, or business teams are sidelined. | Miscommunication, scope changes, and adoption issues emerge downstream. |

| Cultural resistance / change fatigue | Previous failed pilots, unclear communication, and low trust undermine engagement. | Users treat new systems as “yet another fad” and revert to old ways. |

| Overambitious scope / moving too fast | Trying to digitalize entire ERP, supply chain, manufacturing, and sales at once. | Overload in change, delays, and cost overruns. |

| Poor execution discipline / weak governance | Lack of strong product ownership, shifting priorities, and weak change control. | Leads to slippage, feature creep, and fragmentation. |

| Neglect of change management / human dimension | Focus on rollout, minimal training, and no stakeholder planning. | Even good systems fail due to user non-adoption. |

These issues are often interconnected: poor strategy invites misalignment, which invites resistance, which leads to weak execution and eventual collapse. McKinsey’s research underscores that leaders often get distracted by peripheral agendas — dashboards, reports, or KPIs — instead of focusing relentlessly on tangible outcomes.

A Better Way: From Problem to Solution to Change

To avoid these traps, transformation must flow in a

business-first manner, with digital as an enabler. DX Advisory Solutions recommends a three-phase framework:

Discover → Build & Pilot → Scale & Embed. Each phase integrates technical, process, and human dimensions.

1. Discover: Diagnose and Prioritize

The discovery phase is where success or failure is decided. Instead of rushing into technology selection, organizations should begin with a clear-eyed diagnostic of their value streams, capabilities, and constraints. This involves quantifying inefficiencies — yield losses, downtime, process delays, excess inventory, or rework — and understanding what capabilities are missing to address them.

The goal is not to audit technology, but to evaluate business capability gaps. Through process mapping, workshops, interviews, and benchmarking, leaders can identify where decisions are still manual, where data visibility is lacking, and where automation or advanced analytics could create measurable value.

Once pain points are known, teams should translate them into hypotheses — “if we improve predictive scheduling, OEE could rise 5%,” or “if we integrate quality and maintenance data, scrap rates could drop 10%.” These hypotheses form the backbone of business cases, prioritized by potential impact and ease of execution.

Finally, the target operating model should be defined: key processes, roles, and success metrics that will guide execution. This stage is also the time to assess readiness — culture, skills, and risk appetite. Skipping this phase is like building on sand; diagnostics and readiness assessment provide the stable foundation transformation needs.

2. Build & Pilot: Learn Fast, Iterate, De-Risk

With clarity on what matters most, the next step is to

build pilots that learn fast and de-risk big bets. Instead of enterprise-wide rollouts, focus on a minimal viable process or product — a single production line, a maintenance process, or a customer workflow — to test hypotheses in a contained environment.

Each pilot should begin with process redesign before automation. The goal is to fix what’s broken, not just digitize inefficiency. Business users should co-own process redesigns, defining decision points, handoffs, and data inputs. Technology then becomes the enabler of a smarter process, not its master.

User involvement is critical. By engaging operators, engineers, or managers in the pilot phase, adoption barriers are dramatically reduced. Change management should also start here — not at the end. Training, communications, and leadership sponsorship should run in parallel with product development. Celebrate small wins, gather feedback, and showcase outcomes to build momentum.

Governance during this phase is about clarity and accountability. Each pilot should have a clearly empowered product owner responsible for outcomes, not just delivery. Measure business impact — cost reduction, throughput gains, lead-time improvements — and evaluate scalability potential. If a pilot doesn’t work, document the lessons and pivot. Failure at this stage is affordable learning; failure after scale is costly rework.

3. Scale & Embed: Deploy at Enterprise Pace, Anchor Change

Scaling is where transformation either creates enterprise value or loses traction. Scaling should be incremental, disciplined, and supported by strong governance. Rolling out improvements in phases — by plant, region, or function — allows learning loops and continuous refinement.

At this stage, organizations should focus on capability uplift: building data literacy, analytics skills, and cross-functional understanding. Centers of excellence or capability hubs can institutionalize expertise and support scaling across units.

Change governance becomes paramount. Establishing a transformation steering committee, a change network, and a continuous feedback structure ensures alignment between business and technology. As new systems roll out, reinforcement mechanisms — incentives, updated KPIs, redefined roles — must anchor behavior change.

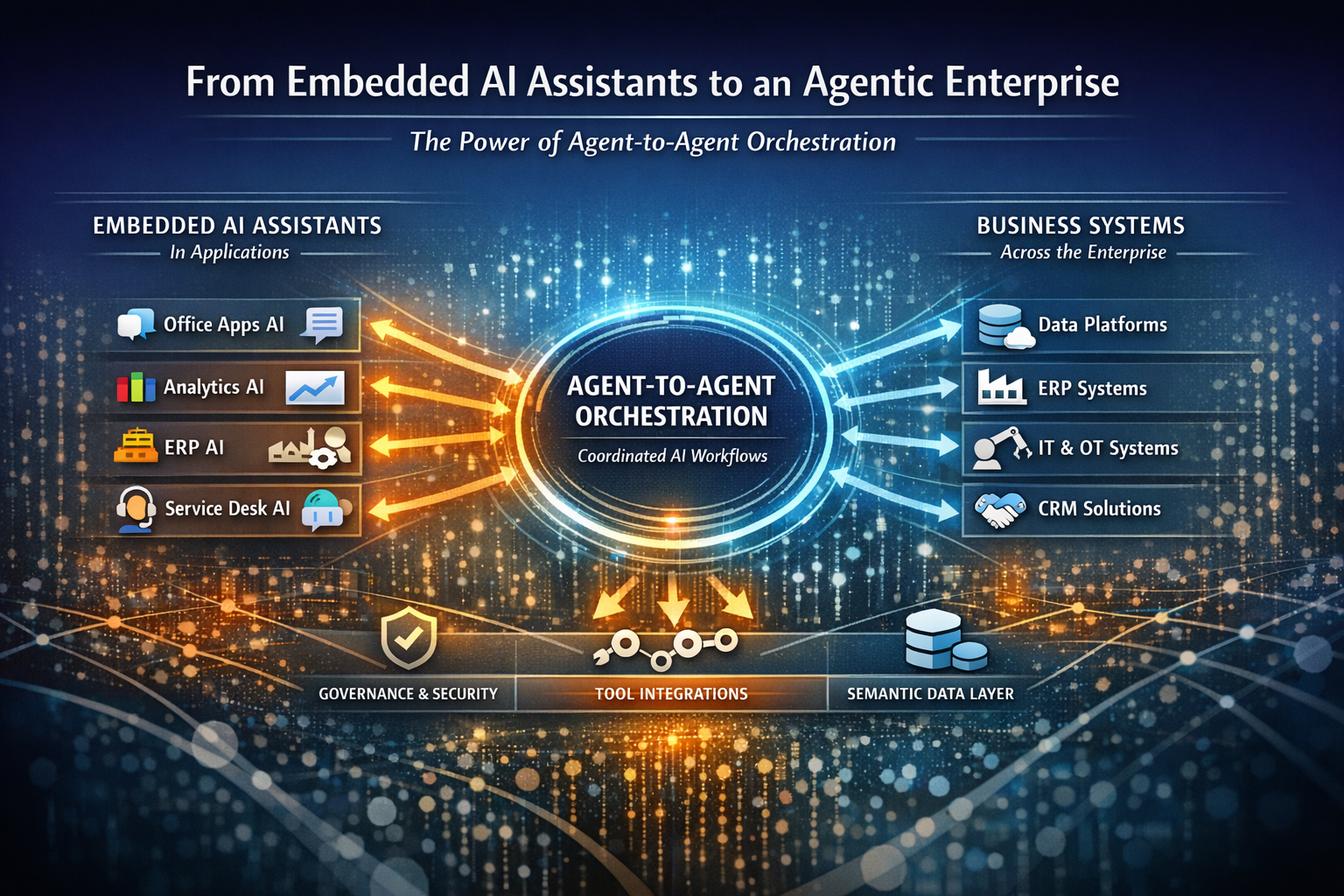

Finally, sustainment and innovation are what differentiate temporary projects from lasting transformation. The best organizations embed experimentation and “safe-to-fail” pilots into their DNA, continually testing new use cases, refining processes, and adapting technology. Architecturally, they invest in modular, interoperable platforms that can evolve — avoiding rigid systems that stifle innovation.

Change Management: The (Often Missing) Secret Sauce

Even the best automation or AI solution fails without adoption. Change management must be built into every stage of transformation, not bolted on at the end. Traditional change models assume a one-time shift from “state A” to “state B.” But digital transformation is perpetual. It disrupts workflows, identities, and comfort zones — requiring continuous engagement, leadership sponsorship, and empathy.

Modern change management emphasizes six pillars:

visible executive sponsorship, active stakeholder engagement, clear communication of the “why,” role-based training, structured resistance management, and reinforcement through incentives and KPIs. The essence is integration — embedding change within development, not running it as a parallel stream.

What It Means for Executives

For senior leaders—CFOs, CIOs, COOs, CDOs, and CEOs—driving transformation means moving beyond technology procurement to orchestrating value creation, accountability, and culture. CEOs and CFOs must demand that every transformation investment articulate clear, risk-adjusted business value; insist on a diagnostic or discovery phase before major spend; enforce accountability for measurable outcomes—not just milestones—and champion a culture that rewards experimentation, tolerates intelligent failure, and anchors behavior change. CIOs and CDOs should act as translators between business and technology, framing digital opportunities in business terms, promoting modular and low-code architectures only after process design is sound, leading pilots and scaling in close partnership with domain leaders, integrating change, DevOps, and culture initiatives to avoid silos, and tracking adoption metrics as rigorously as delivery metrics. COOs and business unit heads must own their processes end-to-end, embrace co-creation with IT rather than delegation, engage frontline users early and often in pilots and feedback loops, realign KPIs, roles, and incentives to reinforce new ways of working, and serve as visible, consistent sponsors of change within their domains. Across all executive roles, effective sponsorship demands eight disciplines: mandate a discovery phase (3–6 months) before major tech commitments; require value hypotheses and leading indicators—not just project charters; insist on integrated change management, technology, and process design; ensure strong product ownership and alignment between business and IT; review adoption and outcome metrics regularly, not just milestone status; create cross-functional change networks or champion forums; allocate budget and time for experimentation and safe-fail pilots; and, above all, treat transformation as a continuous journey of adaptation and learning, not a one-time initiative.

Illustrative Example (Process Manufacturing Client)

A mid-sized

process manufacturing client engaged DX Advisory Solutions after several failed attempts to improve

Overall Equipment Effectiveness (OEE) using a technology-first approach. The company had invested in IoT sensors and AI-based predictive tools, expecting immediate improvements in uptime and throughput. However, despite the new dashboards and algorithms, OEE barely moved — because the root causes of downtime weren’t technological.

During the discovery phase, DX Advisory’s diagnostic revealed that the

largest performance losses were not equipment failures but rather

frequent changeovers, undocumented micro-stoppages, material delays, and inconsistent operator visibility. These insights redirected focus away from more software licenses toward redesigning core workflows and decision loops.

A pilot was launched in one production area. The process was re-engineered to simplify changeovers, integrate quality and maintenance logs, and deploy

operator-facing dashboards that made production and downtime data visible in real time. In parallel, frontline teams received targeted training on interpreting machine data and taking corrective actions without escalation.

Within two quarters, OEE improved by

8%, driven by faster problem response and reduced idle time — not by adding more sensors, but by enabling better human-machine collaboration. The success of the pilot created internal momentum: the model was replicated across other sites, coupled with a

change network of plant champions, refined incentives, and digital capability workshops.

Because the transformation began with business pain points, not technology procurement, adoption was high, the improvements were sustained, and the organization built a scalable playbook for digital expansion across its network.

Common Objections and Risks — and How to Mitigate

A big part of adoption and change management is dealing with objections pragmatically. Below are common resistance patterns and their mitigations:

| Objection / Risk | Response / Mitigation |

|---|---|

| “We must move fast, or we’ll be disrupted.” | Speed matters, but not at the expense of clarity. Focus on a few high-impact pilots; momentum beats breadth. |

| “We can’t fund a long diagnostic phase; we need ROI now.” | Treat it as portfolio hedging: if a pilot fails, you lose less. Diagnostics are risk mitigation, not delay. |

| “The business is too siloed; alignment is impossible.” | Form cross-functional “transformation squads” with shared metrics across silos. |

| “Our culture is rigid; people resist everything new.” | Start with early adopters and change agents; celebrate small wins publicly; scale gradually. |

| “We’ve tried technology projects before and failed.” | Use that memory as an asset: document lessons and rebuild credibility through low-risk pilots. |

| “We have legacy systems; we can’t rip and replace.” | Adopt hybrid architectures with APIs and selective modernization; don’t let legacy fear stall progress. |

Final Thoughts

Digital transformation is not a technology procurement — it is a journey of business reinvention. The organizations that win are those that start with diagnosing real value gaps, invest early in process and change readiness, pilot thoughtfully, and scale deliberately while embedding new behaviors and culture.

As an executive leading this charge, your job is to hold the north star of business outcomes, demand accountability for value, and ensure that transformation is lived by people at every level — not just in slide decks or vendor contracts.

About Author:

Towhidul Hoque is an executive leader in AI, data platforms, and digital transformation with 20 years of experience helping organizations build scalable, production-grade intelligent systems.